Introduction to Pellet Machines

A pellet machine, also known as a pellet mill, is a specialized equipment designed to compress and form raw materials into uniform cylindrical pellets. These machines are widely used in various industries, primarily in the production of animal feed, biomass fuel, and various other granulated products. The primary purpose of a pellet machine is to enhance the efficiency of material processing and to facilitate optimal storage and transportation. By turning loose materials into compact pellets, these machines significantly reduce the volume of raw materials and enhance their performance in various applications.

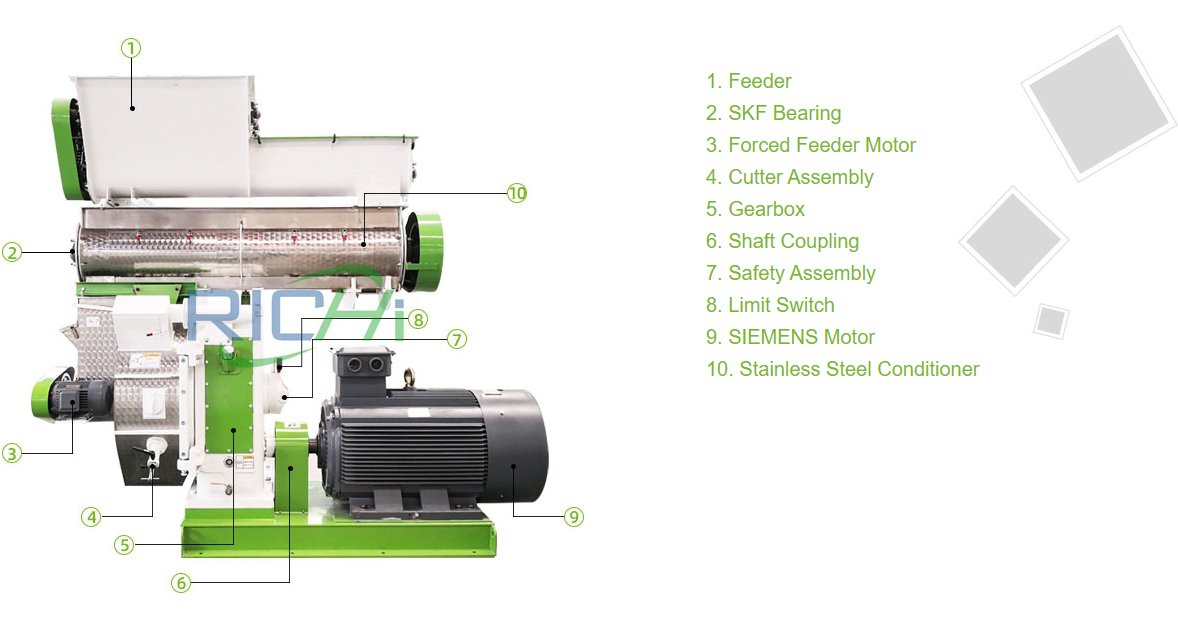

The basic components of a pellet machine include a die, rollers, and a feeding system. The die is a crucial part of the machine where raw materials are compressed into pellets. Rollers exert pressure on the materials as they pass through the die, transforming them into the desired pellet shape. The feeding system ensures a steady and uniform flow of materials into the pelletizing chamber. Together, these components must work in harmony to achieve efficient and consistent pellet production.

Pellet machines are versatile in terms of the range of materials they can process. Commonly, they handle organic materials like wood, straw, and agricultural residues to create biomass pellets for heating and energy production. Additionally, they can process animal feed ingredients such as grains, forages, and protein meals, contributing to the livestock industry’s growth. (https://www.richimanufacture.com/cattle-feed-pellet-machine/)The ability to produce high-quality pellets from various raw materials has made pellet machines invaluable in sectors focusing on sustainability and resource optimization. Their significance continues to rise as industries strive for more efficient and environmentally friendly processing methods.

Applications of Pellet Machines

Pellet machines play a pivotal role in a variety of industries, enabling the efficient production of various types of pellets that serve multiple purposes. One of the most significant applications is in the agricultural sector, where these machines are utilized for producing animal feed pellets. The feed produced by pellet machines is highly nutritious and easy for livestock to consume. By compacting feed materials into pellets, the machines help in reducing waste and enhancing feed efficiency, ensuring better growth rates in animals.

Another prominent application of pellet machines lies in the production of biomass pellets. These pellets are primarily made from organic materials, including wood, agricultural residues, and other biomass feedstocks. As the world shifts towards renewable energy sources, biomass pellets are emerging as a sustainable alternative to fossil fuels. They can be used in residential heating systems or large-scale power plants, contributing to a reduction in carbon emissions and promoting energy independence.

The wood processing industry also benefits significantly from the utilization of pellet machines. These machines effectively convert sawdust and wood shavings into high-quality wood pellets, which can then be used for heating or as a raw material for other manufacturing processes. Furthermore, the use of pellet machines in the food industry allows the production of wood-based flavorings, enhancing the taste of various food items.

In addition to agriculture and renewable energy, pellet machines find applications in the pharmaceutical and chemical industries, where they are used to produce pellets that facilitate the controlled release of medications or chemicals. This versatility makes pellet machines indispensable across various sectors. Thus, from enhancing animal nutrition to contributing to sustainable energy solutions, the diverse applications of pellet machines underscore their importance in modern industrial practices.

Industrial Analysis of Pellet Machines

Pellet machines have become a crucial component in various industrial sectors, particularly in biomass energy production and animal feed manufacturing. Their ability to efficiently compress raw materials into dense pellets has transformed how industries handle biomass waste and feedstock, optimizing both production processes and overall efficiency. Current market data indicates a growing trend in the adoption of pellet machinery across multiple sectors, reflecting an increased focus on sustainable practices and resource conservation.

Recent statistics reveal that the global biomass pellet market is expected to grow significantly, with projections estimating a compound annual growth rate (CAGR) of over 10% from 2023 to 2030. This surge is attributed largely to the rising demand for alternative energy sources and more environmentally friendly practices in production. Pellet machines, therefore, are seeing enhanced production capacities, with advanced models capable of producing upwards of 10 tons of pellets per hour. Such productivity levels not only assure a consistent supply of raw materials but also make the operations more cost-effective.

In addition to their operational efficiency, pellet machines are associated with reduced transport costs and lower carbon footprints. The densification process reduces the volume of raw materials, allowing for more efficient logistics and storage solutions. Moreover, many manufacturers are investing in technology that enhances the energy efficiency of pellet production, further improving the cost-effectiveness compared to traditional processing methods. The market has been influenced by heightened awareness of sustainability, leading industries to implement pellet machines as part of their operational strategies.

In conclusion, the analysis of pellet machines highlights their rising significance in industrial applications, driven by market trends emphasizing efficiency, cost-effectiveness, and sustainability. The continued evolution and innovation in pellet technology are expected to bolster their adoption across various sectors, presenting opportunities for growth and increased productivity.

Classification of Pellet Machines

Pellet machines play a critical role in the process of transforming raw materials into valuable pelletized products, a method commonly used in industries such as agriculture, food, and waste management. These machines can be classified based on various criteria including structure, capacity, and application. The primary types of pellet machines are the flat die and ring die variants, each serving distinct purposes and featuring different operational characteristics.

The flat die pellet machine is recognized for its two-dimensional design, where the die remains stationary while the rollers turn to compress the material into pellets. This type is generally more suited for small-scale production or artisanal processes, as it is often more affordable and simpler to operate. The flat die pellet machines are particularly effective for producing biomass pellets from various feedstock, including agricultural residues and sawdust, offering flexibility in the size and diameter of the pellets produced.

In contrast, the ring die pellet machine operates on a three-dimensional cycle. In this system, both the rollers and the die are rotated, allowing for continuous feeding and enhanced production capacity. The ring die design tends to facilitate larger scale production, making it ideal for industrial applications. This type of pellet machine is particularly efficient for processing a wide range of materials, including animal feed, wood pellets, and plastic waste, thus supporting diverse production needs.

Additionally, pellet machines can also be categorized based on their capacity. Small-scale machines are intended for personal or local use, whereas large-scale industrial pellet machines are designed to handle high-volume production, delivering consistent quality and efficiency. Understanding these classifications allows businesses to select the appropriate pellet machine that aligns with their operational requirements, ensuring optimal performance and output.

Working Principles and Process Flow of Pellet Machines

Pellet machines operate based on well-defined principles that facilitate the conversion of raw materials into pellets. The process begins with the feeding of raw materials, which can include agricultural residues, wood shavings, or other biomass sources, into the machine’s hopper. This initial input is crucial, as the quality and composition of the raw material directly impact the final pellet quality.

Once the raw materials are loaded into the hopper, they are moved into the conditioner. This component serves to pre-treat the materials by adding steam or water, which enhances moisture content and modifies the material’s texture. This step is vital as it aids in softening the feedstock, making it more pliable for shaping. Proper conditioning ensures a consistent feed flow, which is essential for uniform pellet production.

Following conditioning, the material is transported to the main die and roller assembly within the pellet machine. The die contains several holes through which the softened raw material is forced under high pressure. Here, the rollers compress the materials against the die, forming small, cylindrical pellets. The heat generated by this compression, and the friction from the rollers, further helps to bind the particles together, thanks to the natural lignin present in many biomass materials.

Once the pellets are formed, they exit the die and enter the cooling phase. Cooling is crucial as it helps in the solidification of pellets, reducing moisture content and enhancing their durability. The cooled pellets are then screened to remove any fines and dust, resulting in a uniform product ready for packaging or storage.

This overarching flow from raw material input to finished pellet output highlights the essential components of a pellet machine and their respective roles. Understanding these principles provides insight into the efficiency and effectiveness of the pelletizing process, paving the way for optimized production in various agricultural and industrial applications.

Choosing the Right Pellet Machine

Selecting the appropriate pellet machine is crucial for achieving optimal production performance. One must first evaluate the capacity requirements of the intended operation. The capacity of a pellet machine refers to the amount of material it can process within a given time frame, typically measured in kilograms per hour. Understanding the production demands will help determine whether a small-scale or large-scale pellet machine is required. For instance, businesses focusing on low-volume production may benefit from a smaller unit, while large manufacturers need heavy-duty machines that can handle high output.

Next, it is essential to consider the type of materials that will be processed. Pellet machines are designed to work with various raw materials, including wood, agricultural residues, or feedstock. Each material has its unique characteristics, such as moisture content and particle size, which can influence pellet quality. Therefore, potential buyers should ensure that the pellet machine they select is compatible with their specific feedstock. For example, a pellet machine suitable for wood production may not be effective for processing agricultural wastes.

Cost is another critical factor in the decision-making process. Investing in a pellet machine requires careful financial consideration, encompassing not only the initial purchase price but also potential operational costs. It is advisable to compare different models and manufacturers to assess the total cost of ownership. In real-life scenarios, companies have often opted for higher-priced machines that offer greater durability and efficiency, resulting in lower long-term operational costs.

Case studies reveal that successful businesses prioritize thorough research in their selection process, ensuring their chosen pellet machine aligns with their production needs. By rigorously assessing capacity, material type, and cost, operators can make informed decisions that lead to successful pellet production.

Selecting a Reliable Pellet Machine Supplier

When searching for a reliable pellet machine supplier, it is critical to consider several key criteria that can significantly influence your production efficiency and overall success. One of the foremost aspects is the supplier’s ability to customize the pellet production line. Different materials and production goals necessitate unique configurations, and a supplier that can tailor their equipment to meet your specific needs will provide a considerable advantage. Customization can involve adjustments to the pellet machine’s size, capacity, and even the technology used for pelletizing, which can result in higher quality pellets and improved operational efficiency.

An equally important factor to examine is the manufacturing capabilities of the supplier. A reputable pellet machine supplier should demonstrate a commitment to high-quality standards and possess advanced technological expertise. This often translates to better machinery that operates at optimal efficiency, thereby reducing downtime and maintenance costs. Additionally, investigating whether the supplier has experience in producing the type of pellet machine suited to your needs will give you confidence in their capability to deliver a reliable product tailored to your operations.

Customer service quality also plays a crucial role in selecting a pellet machine supplier. A responsive and knowledgeable customer support team can provide valuable assistance during the purchasing process and beyond. This includes providing technical support, spare parts availability, and guidance on machinery operation. Efficient after-sales service fosters a strong partnership that is essential for addressing any challenges that arise during production. By choosing a supplier with exceptional customer service, you can minimize disruptions and ensure smooth operation of your pellet machine.

In conclusion, selecting the right pellet machine supplier involves assessing their customization capabilities, manufacturing quality, and customer support. Making an informed choice can drive your operations towards greater productivity and success in pellet production.

Spotlight on Richi Machinery Company

Richi Machinery Company, based in Henan, China, stands as a prominent manufacturer within the pellet machine sector. Established with a commitment to innovation and excellence, Richi Machinery specializes in the design and production of a wide range of pellet machines that cater to various industries, including biomass, animal feed, and fertilizer production. The company has developed a robust reputation for delivering high-quality equipment and personalized service tailored to the specific needs of its clients.

One of the key factors that sets Richi Machinery apart is its focus on custom pellet production lines. Understanding that different customers have unique requirements, the company offers bespoke solutions that enable clients to optimize their production processes. Richi’s team of engineers and technicians works closely with customers to design pellet machines that meet their specific operational demands. This level of customization not only enhances efficiency but also contributes significantly to the overall productivity of the end-user.

Furthermore, Richi Machinery is well-known for its turnkey project execution capabilities. The company manages projects from inception to completion, ensuring that every phase is handled with the utmost professionalism. This comprehensive approach provides customers with a seamless experience, as they can rely on Richi to oversee the installation, commissioning, and training necessary for their pellet machine operations. Such dedication to client satisfaction has led to numerous successful partnerships, further solidifying Richi’s position as a leader in the pellet manufacturing industry.

Richi Machinery’s product range is extensive, encompassing not only pellet machines but also supporting equipment and systems for material preprocessing, storage, and packaging. The company’s innovative designs and commitment to quality have resulted in numerous success stories, with clients from various sectors reporting significant improvements in efficiency and production capabilities. Such achievements underscore Richi Machinery’s role as a trusted provider in the pellet manufacturing landscape.

The Practical Application Value of Pellet Machines

Pellet machines have gained traction across various industries due to their pivotal role in enhancing efficiency and promoting sustainability. These machines are used to convert raw materials into dense, compact pellets, which are not only easy to store but also facilitate efficient transportation. By transforming agricultural waste, wood chips, and other biomass into pellets, businesses can significantly reduce waste disposal costs while creating a valuable product that can be used as a renewable energy source.

One of the primary applications of pellet machines is in the production of biomass pellets. These pellets serve as an environmentally friendly alternative to fossil fuels. By utilizing pellet machines, companies can support their sustainability goals while reducing their carbon footprint. The compact nature of the pellets allows for better combustion in power generation setups, leading to higher energy output and lower emissions when compared to traditional fuels.

Furthermore, the use of pellet machines facilitates the improvement of overall operational efficiency. By automating the pelletization process, businesses can reduce manual labor and minimize errors associated with traditional processing methods. Consequently, this leads to a more streamlined production operation, which often translates to cost savings and improved profit margins.

Economically, the investment in pellet machines can yield significant returns over time. With the growing demand for renewable energy and biomass products, businesses equipped with pellet machines are well-positioned to capitalize on emerging market trends. This advantage is further enhanced as industries pivot towards more sustainable practices driven by regulatory pressures and consumer preferences.

In conclusion, the practical application value of pellet machines extends across sustainability, efficiency, and economic benefits. As industries continue to evolve and pivot towards greener alternatives, the role of pellet machines will likely become even more pronounced, driving innovations that contribute to a more sustainable future.

Frequently Asked Questions about Pellet Machines

Pellet machines are essential tools used in various industries for producing pellets from biomass or feed materials. Many users often have questions regarding their operation, maintenance, and the challenges encountered during pellet production. Below are some common queries along with their answers.

How does a pellet machine work? Pellet machines operate by compressing raw materials into small, cylindrical pellets. The process involves feeding the material into a die, where it is subjected to high pressure and temperature. This causes the lignin in the biomass to soften and bind the particles together, forming pellets. Understanding the operational mechanics of a pellet machine is critical for maximizing efficiency and output.

What are the main types of pellet machines available? There are generally two primary types of pellet machines: flat die and ring die machines. Flat die pellet machines are suitable for small-scale production and are easy to operate, while ring die machines are designed for larger operations, offering increased capacity and efficiency. The selection between these types should consider production scale and material characteristics.

How can I maintain my pellet machine? Regular maintenance is vital for ensuring the longevity and performance of a pellet machine. Key maintenance tasks include cleaning the machine after use, lubricating critical components, regularly checking for wear and tear on the die and rollers, and ensuring the electrical systems are functioning correctly. Establishing a routine maintenance schedule helps mitigate potential operational issues and enhances the overall productivity of the machine.

What challenges might I face when producing pellets? Various factors can affect pellet production, including the quality of raw materials, moisture content, and machine settings. Inconsistent feedstock can lead to poor pellet quality, while inadequate moisture levels may cause binding issues. It is essential to monitor these parameters continuously to ensure optimal production outcomes.

By addressing these common questions, users can better navigate the complexities of utilizing pellet machines and ensure that they achieve their production goals efficiently.