The maintenance of Goat Feed Pellet Making Machines during production is essential to ensure optimal performance, efficiency, and the longevity of the equipment. Proper maintenance not only helps in producing high-quality goat feed pellets but also prevents unexpected breakdowns and ensures operator safety. Here’s a detailed overview of the special maintenance requirements:

Importance of Maintenance

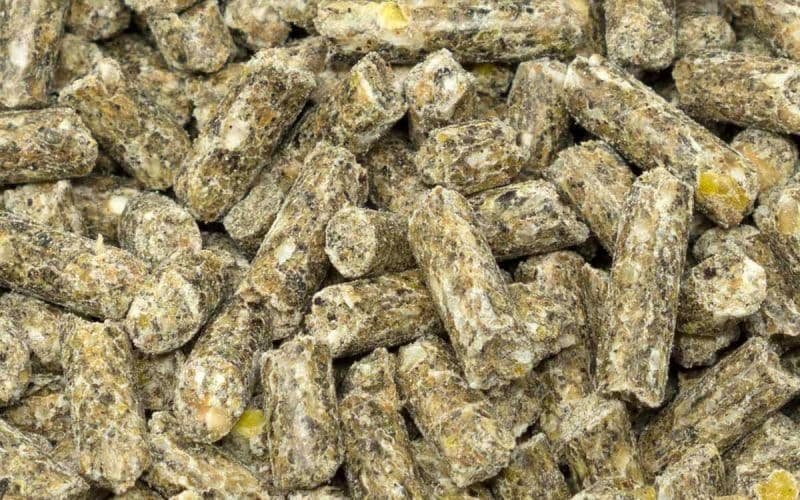

- Consistent Pellet Quality: Regular maintenance ensures that the pellets produced are uniform and meet the nutritional needs of goats.

- Production Efficiency: Properly maintained machines run more efficiently, reducing energy consumption and increasing throughput.

- Longevity: Regular upkeep extends the lifespan of the machine, protecting your investment.

- Safety: Regular maintenance helps prevent accidents, ensuring a safe working environment.

- Compliance: Adhering to maintenance schedules is crucial for meeting food safety regulations.

Key Components Requiring Special Attention

- Die and Rollers:

- These are crucial for the pelleting process and endure the most wear. Regular inspections for wear patterns and damage are essential. Dies and rollers may require periodic replacement or resurfacing.

- Conditioner:

- Responsible for adjusting the moisture content and temperature of the feed mixture. It should be cleaned regularly to prevent residue buildup and inspected for proper functioning of steam valves and nozzles.

- Feeder:

- Ensures a consistent feed rate into the pellet mill. Regular calibration and inspection of the auger or screw for wear or damage are necessary.

- Cooling System:

- Critical for maintaining pellet quality. Regular cleaning of the cooling bed and fans, as well as inspection of airflow and temperature controls, is important.

- Drive System:

- Powers the entire process. Regular lubrication of bearings and gears and checking the tension and wear of belts or chains are required.

Routine Maintenance Tasks During Production

- Daily Inspections: Perform visual checks of all machine components, monitor temperature and pressure, and listen for unusual noises.

- Lubrication: Follow the manufacturer’s lubrication schedule and check oil levels regularly.

- Cleaning: Regularly clean the die and roller assembly, conditioner, feeder, and remove dust from electrical components.

- Adjustments: Fine-tune the roller-to-die gap, adjust feeder settings, and calibrate moisture and temperature controls.

- Record Keeping: Maintain detailed logs of maintenance activities and track performance metrics.

Preventive Maintenance Strategies

- Scheduled Maintenance: Develop a comprehensive maintenance schedule based on manufacturer recommendations and plan regular downtime for thorough inspections.

- Predictive Maintenance: Use vibration analysis, thermal imaging, and oil analysis to detect early signs of wear and prevent breakdowns.

- Spare Parts Management: Keep an inventory of critical spare parts and establish relationships with suppliers for quick delivery.

- Operator Training: Train operators on proper machine operation and maintenance tasks, encouraging them to report any issues promptly. (Related post: cattle feed plant project)

Special Considerations for Goat Feed Production

- Ingredient Variability: Different ingredients can affect wear patterns on dies and rollers, necessitating regular inspection and adjustment.

- Moisture Control: Precise moisture levels are crucial for goat feed quality, so regular calibration and maintenance of moisture sensors and steam systems are vital.

- Hygiene Standards: Implement thorough cleaning and sanitization protocols to meet strict hygiene standards in goat feed production.

Addressing Common Issues

- Die Blockage: Regularly inspect and clean die holes to prevent blockages and use appropriate die selection and feed formulation.

- Uneven Pellet Quality: Adjust the roller-to-die clearance and ensure even feed distribution across the die surface.

- Overheating: Maintain cooling systems and monitor production rates to prevent overheating.

- Excessive Fines Production: Inspect and replace worn dies and rollers and adjust conditioning parameters.

Technology and Maintenance

- IoT Sensors: Use sensors to monitor machine performance in real-time and predict maintenance needs.

- Automated Lubrication Systems: Install systems that automatically apply lubricants at specified intervals.

- Digital Maintenance Logs: Utilize digital platforms for efficient record-keeping and trend analysis.

- Remote Monitoring: Implement systems for remote monitoring and diagnostics.

Safety Considerations

- Lockout/Tagout Procedures: Implement strict procedures for de-energizing and securing machines during maintenance.

- Personal Protective Equipment (PPE): Ensure that maintenance personnel use appropriate PPE.

- Confined Space Protocols: Follow proper protocols for maintenance in confined spaces, such as large mixers or storage bins.

Conclusion

Special maintenance of Goat Feed Pellet Making Machines is vital for consistent production, efficient operation, and longevity. By adhering to a comprehensive maintenance strategy, operators can ensure the machines run smoothly, produce high-quality feed, and meet the growing demand in the market. With careful attention to the machine’s components, routine tasks, preventive strategies, and safety considerations, these machines can continue to serve as valuable assets in feed production operations.