Selecting the ideal twin-screw pet food extruder machine manufacturer is critical for ensuring the quality, efficiency, and scalability of your pet food production process. The decision requires a thorough evaluation of various factors to find a partner who aligns with your business needs and long-term goals. Here’s a breakdown of the key considerations:

1. Experience and Expertise

- Industry Track Record: Prioritize manufacturers with extensive experience in pet food extrusion, such as Buhler, Coperion, and IDAH.

- Specialization: Choose companies that have a deep understanding of pet food formulations and processing requirements, demonstrated through successful projects and a robust portfolio.

2. Range of Extruder Models

- Model Variety: Ensure the manufacturer offers a range of extruders to meet different production scales, from small batch to large commercial outputs.

- Customization: Look for the ability to tailor extruder models to specific production needs, ensuring flexibility as your business grows.

3. Technological Innovation

- R&D Investment: Opt for manufacturers that invest in research and development, continually improving extruder technology to enhance product quality and efficiency.

- Patented Technologies: Consider companies with patented innovations that can give you a competitive edge in the market.

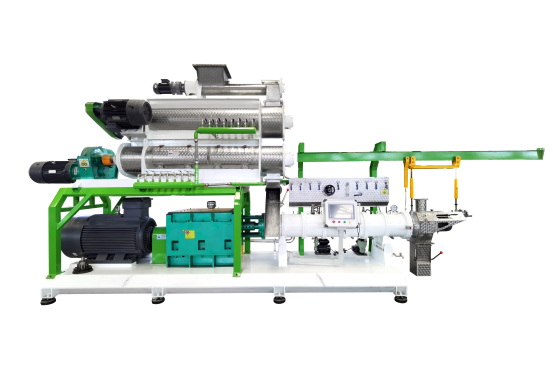

4. Quality of Construction

- Materials: Check that the twin screw extruders are made with high-quality, food-grade materials like stainless steel to ensure durability and safety.

- Build Integrity: Robust construction and wear-resistant components are essential for long-term reliability and minimal maintenance.

5. Process Control and Automation

- Advanced Controls: Look for extruders equipped with precise temperature and pressure controls, recipe management, and data logging features.

- User Interface: A user-friendly interface, such as HMI touch screens, is vital for easy operation and monitoring.

6. Flexibility and Customization

- Adaptability: The manufacturer should offer customization options, including different screw configurations, die shapes, and feeding systems, to accommodate various pet food products.

- Case Studies: Review case studies, like those from Diamond America, that demonstrate the manufacturer’s ability to create custom solutions for unique products.

7. Energy Efficiency and Sustainability

- Efficiency Features: Consider manufacturers that prioritize energy-efficient designs, with optimized motor systems and heat recovery options to reduce operational costs.

8. Ease of Cleaning and Maintenance

- Sanitation: Choose extruders designed for easy cleaning, with features like quick-change components and CIP systems to maintain hygiene standards.

- Maintenance: Ensure easy access to internal parts for routine maintenance, minimizing downtime.

9. Compliance with Food Safety Standards

- Regulatory Adherence: The manufacturer should comply with FDA regulations, HACCP standards, and GFSI guidelines to ensure the safety and quality of your pet food products.

10. After-Sales Support

- Global Network: A strong after-sales support network is crucial for timely assistance, spare parts availability, and ongoing training.

- Remote Support: Look for manufacturers offering remote diagnostics and support to quickly address any issues that arise.

11. Reputation and References

- Customer Feedback: Ask for references from current users and look for online reviews or testimonials that reflect the manufacturer’s reputation in the industry.

- Proven Success: Look for documented successes in similar applications to your own, which can provide confidence in your decision.

12. Cost and Value Proposition

- Total Cost of Ownership: Evaluate the extruder’s initial purchase price against long-term costs, including energy, maintenance, and potential productivity gains.

- Return on Investment: Consider the overall value, not just the upfront cost, to ensure the best investment for your business.

13. Scalability and Future-Proofing

- Growth Potential: Choose manufacturers that offer scalable solutions, allowing you to upgrade or expand the extruder system as your business grows.

- Modular Design: Opt for modular designs that can easily accommodate future trends and product innovations.

14. Collaborative Approach

- Partnership: Look for a manufacturer that sees your relationship as a partnership, providing ongoing support for product development, process optimization, and future expansion.

15. Financial Stability

- Manufacturer Viability: Ensure the manufacturer has a solid financial foundation, indicating their ability to support you in the long term with continuous innovation and service.

Conclusion

Selecting the right twin-screw pet food extruder machine manufacturer is more than just a purchase—it’s about forming a long-term partnership that will support your business growth. By considering factors like experience, innovation, quality, customization, and after-sales support, you can choose a manufacturer that aligns with your business objectives and production needs, ensuring success in the competitive pet food market.